Brand:

GAOGEWarranty:

2 YearsCertification:

ISO CEPort:

Ningbo/Shanghai/GuangzhouPackaging Details:

Wooden Case

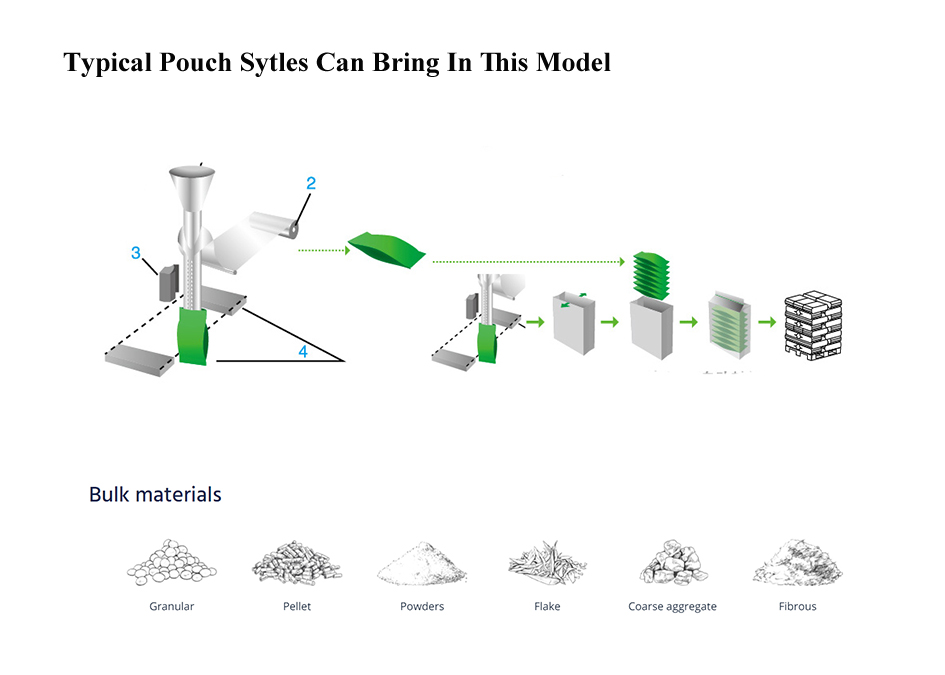

Automatic baling machine is synchronized with one or two packing machine, depending on the product and speed, and pouch collator conveyor, to complete automatically bag loading and baling.

The Automatic baling machine is synchronized with one or multi vertical packaging machine, to complete the packaged pouch products by request order form (one/two/three rows in horizontal) neatly into the baling bag, sealing and take out.

It achieves from bulk materials to be full automatic operation, saving labors, materials and financial inputs, improving the production efficiency and saving transportation costs with safety storage.

Applicable industrials: Agricultures, Foods, Chemicals, Pharmacy etcs. Like rice, sugar, salts, seeds, milk powder, detergent powder, pet foods etc..

Small pouch packing & output- Horizontal conveyor- Climbing & Pressing Conveyor- Accelerating Conveyor- Collator & Discharger- baling machine

|

· Dual Servo Control · Stainless Steel Construction · Auto Positioning Belts · Auto Film Detection |

· Auto Centering Film Spindle · PLC Controls · Color Touch Screen Display · Easy to operate and clean |

· PLC control with stable reliable biaxial high accuracy output and color touch screen, bag-making, measuring, filling, printing, cutting , finished in one operation

· Separate circuit boxes for pneumatic control and power control. Noise is low, and the circuit is more stable

· Film-pulling with servo motor double belt: less pulling resistance, bag is formed in good shape with better appearance, belt is resistant to be worn-out

· External film releasing mechanism: simpler and easier installation of packing film

· Adjustment of bag deviation just needed to be controlled by the touch screen. Operation is very simple

· Close down type mechanism, defending powder into inside of machine

|

Model |

GVF-1100 |

|

Bag Styles |

Pillow Bag, Gusseted Bag |

|

Bag Width |

100 to 535mm (3.9 to 21") |

|

Product Characteristic |

80 to 650mm (3.1 to 25.6") |

|

Film width |

≤1100mm (43.3'') |

|

Dosing System Compatible |

Granules, Powders, Liquids, Pastes |

|

Running Motion |

Intermittent |

|

Working Efficiency |

5-25 bags / min |

|

Control By |

PLC with HMI Touch Screen |

|

Date Coding Can Be |

Hot Stamping Coder, Thermal Transfer Coder, Label Applicator |

|

Options Available |

Perforation, Dust Absorb, Seal PE Film, SS Frame, SS & AL Construction, Nitrogen Flushing, Coffee Valve, Air Expeller |

|

Power & Voltage |

6 KW |

|

Compress Air |

0.7 MPa 0.5 M3/min |

|

Dimensions |

1700*1270*1900mm (66.9*50*74.8") |

|

Machine Weight |

1200 KGS |

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Copyright © 2026 AnHui Gaoge Intelligent Equipment Co.,Ltd.. All Rights Reserved.

IPv6 network supported

Friendly Links :

Carton packing machine manufacturer Industrial Cooling Systems Chillers Packing Machine Manufacturer Plastic Cup Making Machine Drip Coffee Bag Packing Machine Oil Purification Machine Bottle Filling Machine hose clamp machine Vision Counting Packaging Machine Balloon Production Line Paper Bag Machine Handheld Inkjet Printer ahvsee 4 axis delta robot packaging line vibratory feeder conveyor chinafiltermachine Flooring Extrusion Machine