Widely applied for packing rice, sugar, seeds, pet food, diaper and detergent powder these foods, light industrial commodities & chemical raw materials industries.

Brand:

GAOGEWarranty:

2 YearsCertification:

ISO CEPort:

Ningbo/Shanghai/GuangzhouPackaging Details:

Wooden Case

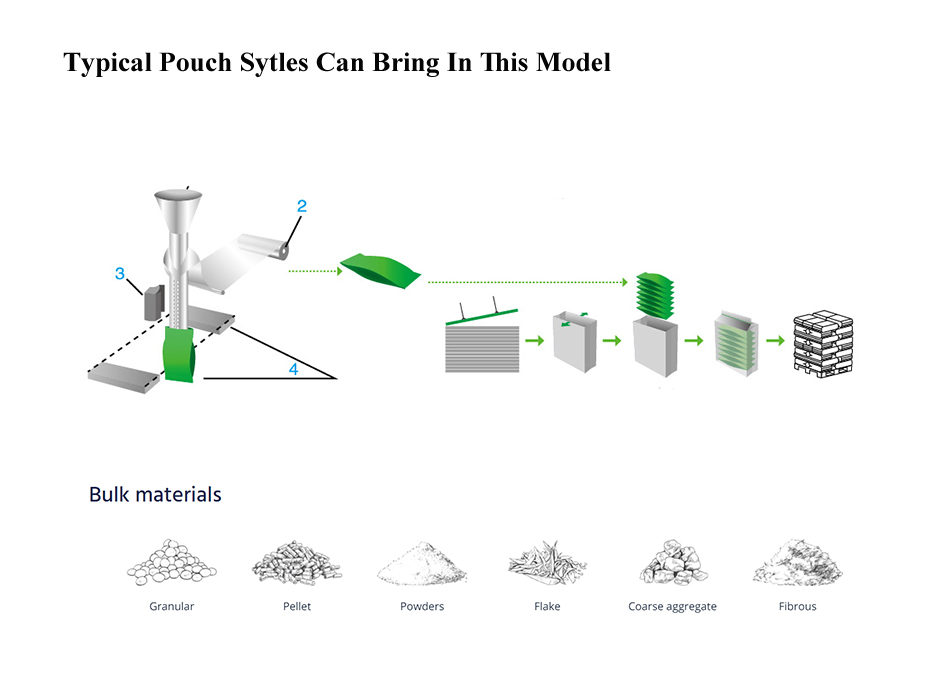

The GW automatic bag placer system is perfect for super store and retail demands by achieving top operational efficiencies, it’s design permits the collating of small pouches and vertical arranged separately into the open mouth bag. One row, two row individually or two tows staggered which is by the clients’ request.

Automatic bagging machine for open mouth

bags without gusset, ideal for packaging granular products in a wide range of

formats.

The GW bagging machine is designed to fill

and close pre-formed bags easily and reliably. Ideal for medium and high

production, this bagging machine adapts to the most varied market requirements

of any sector.

The possibility of coupling any weighing or

closing system makes GW the perfect solution for a wide range of granular

products.

* The automatic packaging machine can pack

granular and powder materials into premade open mouth bags automatically, It

can realize automatic bag feeding, bag opening, bag loading, products filling, bag

sealing and others.

*The packed bag is well sealed, suitable

for packing powder and granule, like feed, pet food, seed, rice, salt, fertilizer,

etc.

*Friendly human-machine interface (HMI), it

can providing complete fault diagnosis and solution, and quick switching of

working modes for packing different characteristics materials.

* Controlled by the color touch screen(Siemens),

and has real-time online detection function, which is convenient for different

users

* Stable and reliable running, convenient

maintenance

* Compact design ideal for restricted

packaging rooms

* Individual bag pick-up and opening

* Empty bag (with or without gusset) transfer to filling mouth

* Bag hermetic fastening on filling mouth

* Bag filling (product discharge from scale or dozer) and vibrating

* Closing system: Thermo-sealing and/or multiple sewing, fold and glued etc.

|

Model |

GW-650 |

|

Applicable materials |

granular(good liquidity) |

|

Weighing range |

5 to 50kg (10lb to 110lb) |

|

Bag Matirical |

Woven bag, kraft paper bag, PE bag |

|

Bag Type |

One line pocket, M side pocket |

|

Speed |

3 to 16 bags/min |

|

Ambient temp |

-10°C to +45°C |

|

Electrical |

380V/50Hz, 3phase or customized per specification |

|

Power |

3KW |

|

Air Pressure & Consumption |

0.7Mpa, 0.6 M3/min |

|

Bag size(mm) |

L 900-1100mm x W 550-650mm |

|

Packing weight(kg) |

40-50kg/bag |

Previous:

Bag in Bag Packing MachineNext:

Bag in Bag Open Mouth Bag Placer,Filler & Closer (Sachets in Bag)If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Copyright © 2026 AnHui Gaoge Intelligent Equipment Co.,Ltd.. All Rights Reserved.

IPv6 network supported

Friendly Links :

Carton packing machine manufacturer Industrial Cooling Systems Chillers Packing Machine Manufacturer Plastic Cup Making Machine Drip Coffee Bag Packing Machine Oil Purification Machine Bottle Filling Machine hose clamp machine Vision Counting Packaging Machine Balloon Production Line Paper Bag Machine Handheld Inkjet Printer ahvsee 4 axis delta robot packaging line vibratory feeder conveyor chinafiltermachine Flooring Extrusion Machine